In the complex world of electronic wiring manufacture, efficiency and precision are paramount. The production process demands exacting standards to ensure the final product meets stringent quality requirements. A critical aspect of achieving such standards is effective tension control during the manufacturing process. The Montalvo Corporation, known for its innovative solutions in tension control systems, provides components that significantly boost the productivity of manufacturing operations.

In the complex world of electronic wiring manufacture, efficiency and precision are paramount. The production process demands exacting standards to ensure the final product meets stringent quality requirements. A critical aspect of achieving such standards is effective tension control during the manufacturing process. The Montalvo Corporation, known for its innovative solutions in tension control systems, provides components that significantly boost the productivity of manufacturing operations.

Understanding the Importance of Tension Control

Tension control is vital in the production of electronic wiring, where even the slightest inconsistency can lead to significant quality issues. Proper tension control ensures that the wires are not stretched, compressed, or otherwise damaged, preserving their integrity and functionality. Whether winding, unwinding, or processing, maintaining consistent tension is crucial for avoiding defects and ensuring the reliability of the final product.

Montalvo Corporation’s Solution

The Montalvo Corporation offers a range of products designed to integrate seamlessly into existing manufacturing setups, providing immediate improvements in productivity and quality. From Controllers like the ZEUS and Vanguard, to our lines of Load Cells, Montalvo’s tension control components are engineered for precision, reliability, and ease of use, making them an ideal choice for manufacturers looking to upgrade their machinery. Here are some key benefits:

Precision Tension Control

Montalvo’s advanced sensors and controllers allow for real-time tension measurement and adjustment, ensuring consistent wire tension throughout the production process. This precision minimizes material wastage and reduces the risk of wire breakage or deformation.

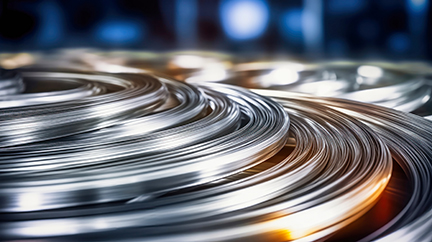

Close-up of aluminum wire spools in a manufacturing plant. Aluminum production.

Enhanced Productivity

By automating tension control, Montalvo’s components reduce the need for manual adjustments, enabling faster production speeds and higher throughput. This automation ensures a more efficient production process, allowing manufacturers to meet demand quicker and with fewer resources.

Easy Integration

Montalvo’s tension control systems are designed to be retrofitted onto existing manufacturing lines with minimal disruption. This ease of integration means that manufacturers can upgrade their operations without significant downtime, quickly reaping the benefits of improved tension control.

Durability and Reliability

Built to withstand the rigors of industrial environments, Montalvo’s tension control components guarantee long-term reliability. This durability reduces maintenance requirements and ensures uninterrupted production, contributing to a lower total cost of ownership.

Targeting the Right Audience

Montalvo Corporation customers, comprising businesses and manufacturers dedicated to enhancing their production capabilities, will find these tension control solutions particularly beneficial. Whether your goal is to upgrade machinery for improved efficiency or to ensure the highest quality in your electronic wiring products, Montalvo’s offerings represent a smart investment.

Making the Right Decision

Choosing to integrate Montalvo Corporation’s tension control components into your manufacturing setup is more than an upgrade—it’s a step toward future-proofing your production processes. With tangible benefits in efficiency, quality, and reliability, these solutions provide a competitive edge in the demanding electronic wiring manufacture sector.

In conclusion, efficient tension control is not merely about maintaining product quality; it’s about elevating your manufacturing process to new heights of productivity and performance. The Montalvo Corporation stands ready to assist customers in achieving these goals, with solutions that meld cutting-edge technology with user-friendly design. Take the step today to upgrade your machinery with Montalvo’s tension control components and experience the difference in your manufacturing output and product quality.