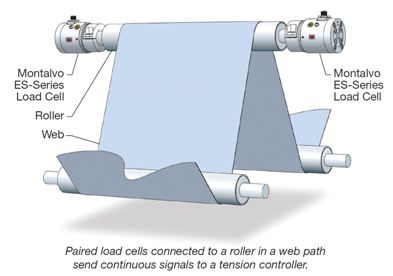

As mentioned here, Load Cells vary by process of which there are many. Knowing how your process runs can help Montalvo provide the right Load Cells for your process. This ensures you get a quality product that will last.

How do we determine Load Cells? We will need to know the following.

- Material running tension(s)

- Web width(s)

- Wrap angle

- Direction of force

- Physical requirements (Dead shaft, live shaft, live roller, space limitations)

- Existing machinery to integrate with or equipment being replaced?

- Existing issues (pain points)

- Along with helping improve customers’ processes or replace existing parts, Montalvo can also perform in-house testing of materials. This service will not only ascertain a desired running tension of material, but may even help solve customers’ historical issues as “we’ve always done it that way”

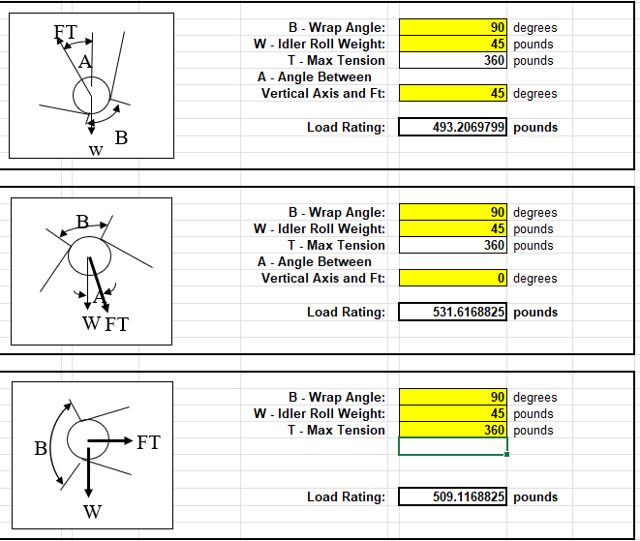

The examples shown here highlight the importance of knowing the application data fully. All three paths have the same wrap angle & web tension, but the direction of the force is different and shows the requirement for a larger load beam. Also, in the two options where the 500# beam is not sufficient, then this also changes the mounting styles available as 1000# beam load cells are only available in flange or pillow block mount for ES load cells.

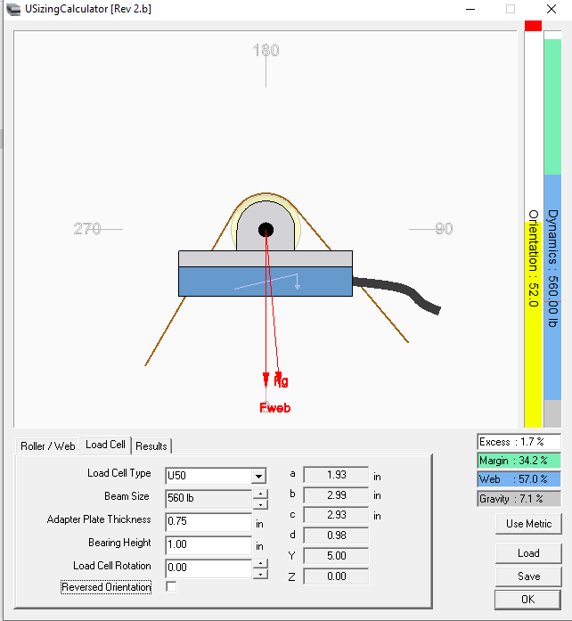

U Series load cells are sized differently due to the construction of the hinged beam, but the theory is the same. Knowing the full application data is key to positive results.