Set It & Forget It Tension Control

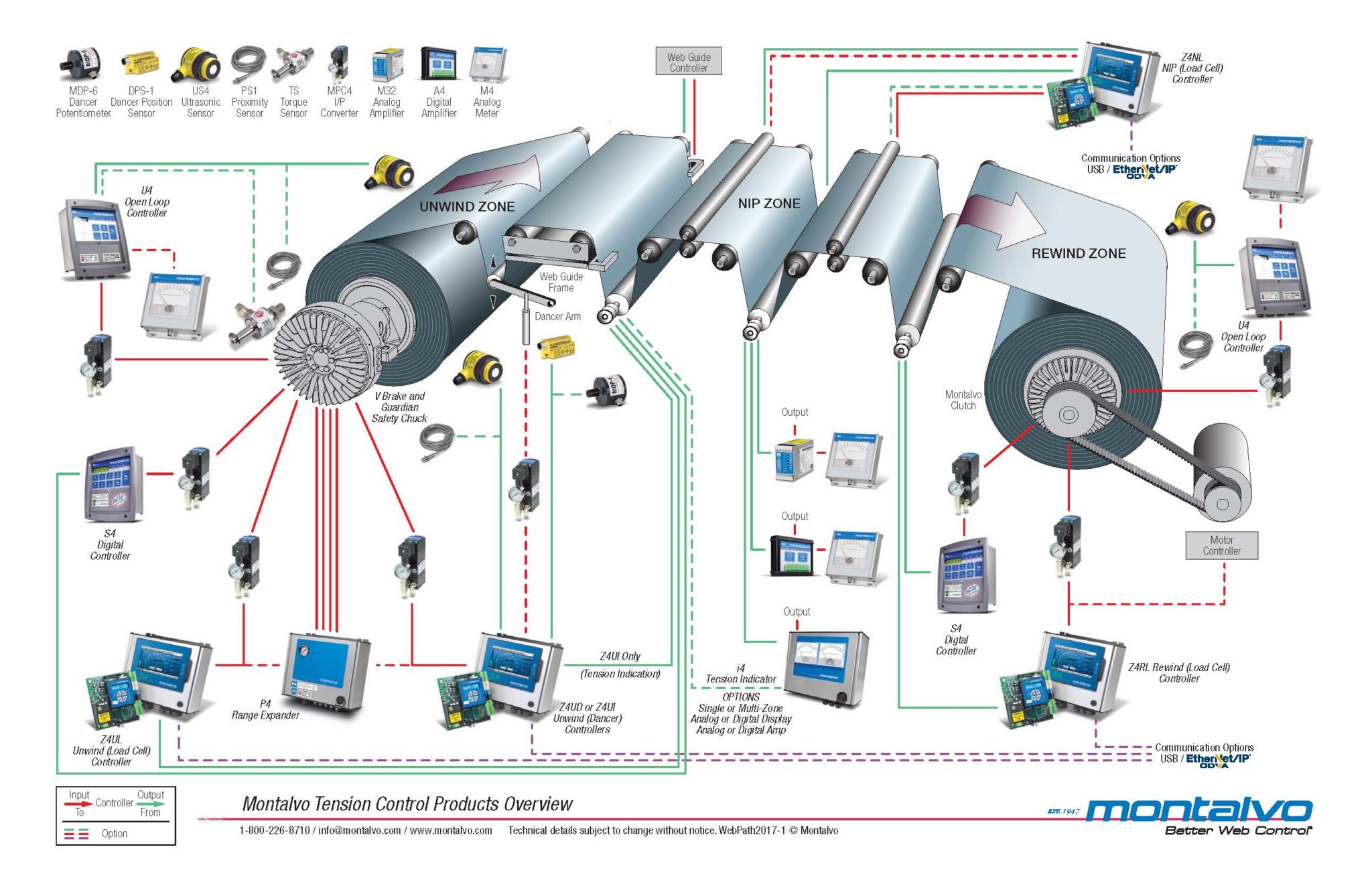

Whether it’s after the web formation process in prepreg or pultrusion processes, looking to add some continuous processing to a hand lay application, or utilizing converting, roll to roll, laminating, sheeting, or slitting processes, Montalvo manufactures a wide range of tension control products suited to your application requirements.

We offer solutions for Pultrusion, Prepreg, Laminating, Converting (slitting, sheeting, r2r, etc.), and Hand-Lay Processes.

- Drop-In and Retrofit Solutions

- Specified to Your Process Parameters

- Automated, Repeatable, High-Quality Control

- Wider Operating Ranges for Running Various Materials

- High Performance, Longer Service Life Components

- Immediate ROI

Pultrusion and Prepreg Processes

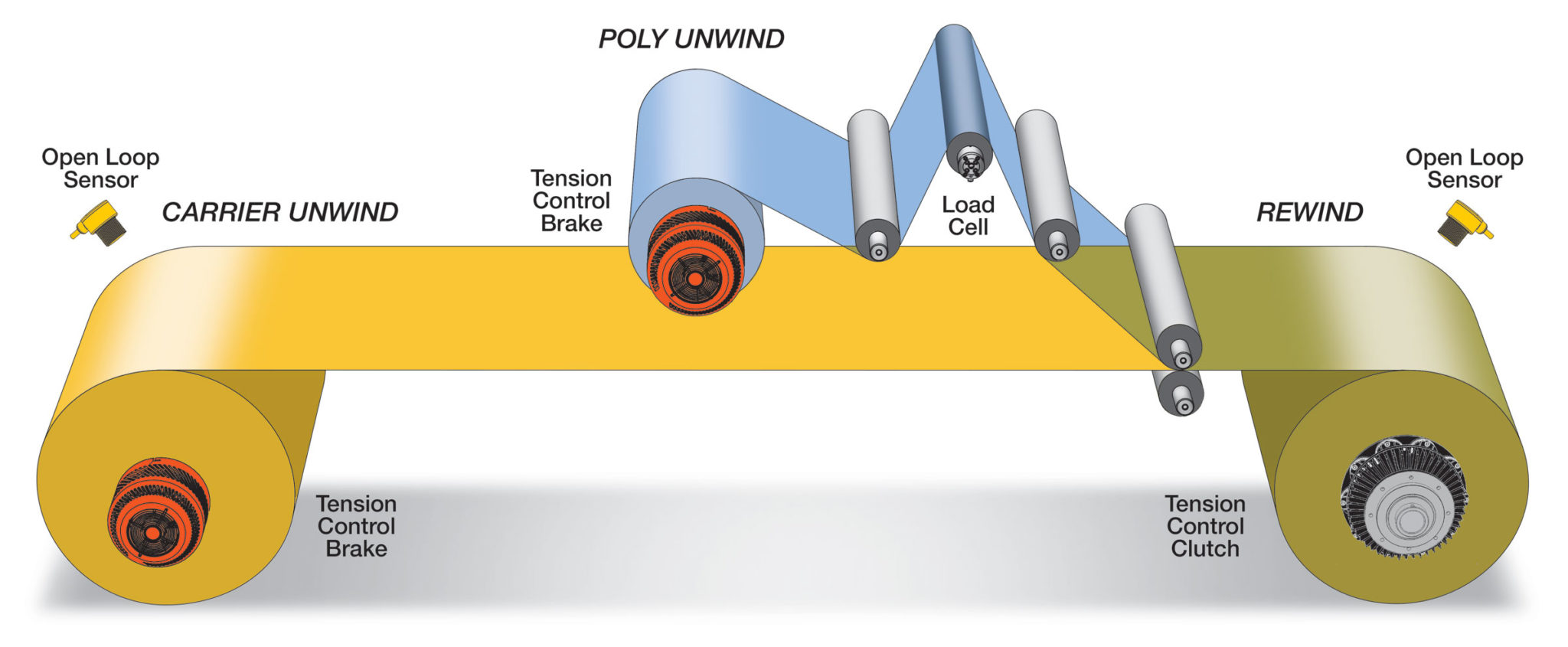

Web tension control on the formed mat, as well as any utilized carrier sheets, is critical to high-quality processing in pultrusion and prepreg applications. Carrier sheet tension control ensures wrinkles, bagginess, breaks, and other defects do not occur, while tension control on the mat itself ensures uniform resin application (if applied to the mat) with no necking down/stretching, breaks, or telescoping during additional processing and rewind/take-up.

Ensure higher quality production with less scrap by easily incorporating tension control components into your intermediate processing zones, or rewind/takeup zone after your mat/web has been formed (as well on the tows themselves)!

Upgrade Your Pultrusion or Prepreg System

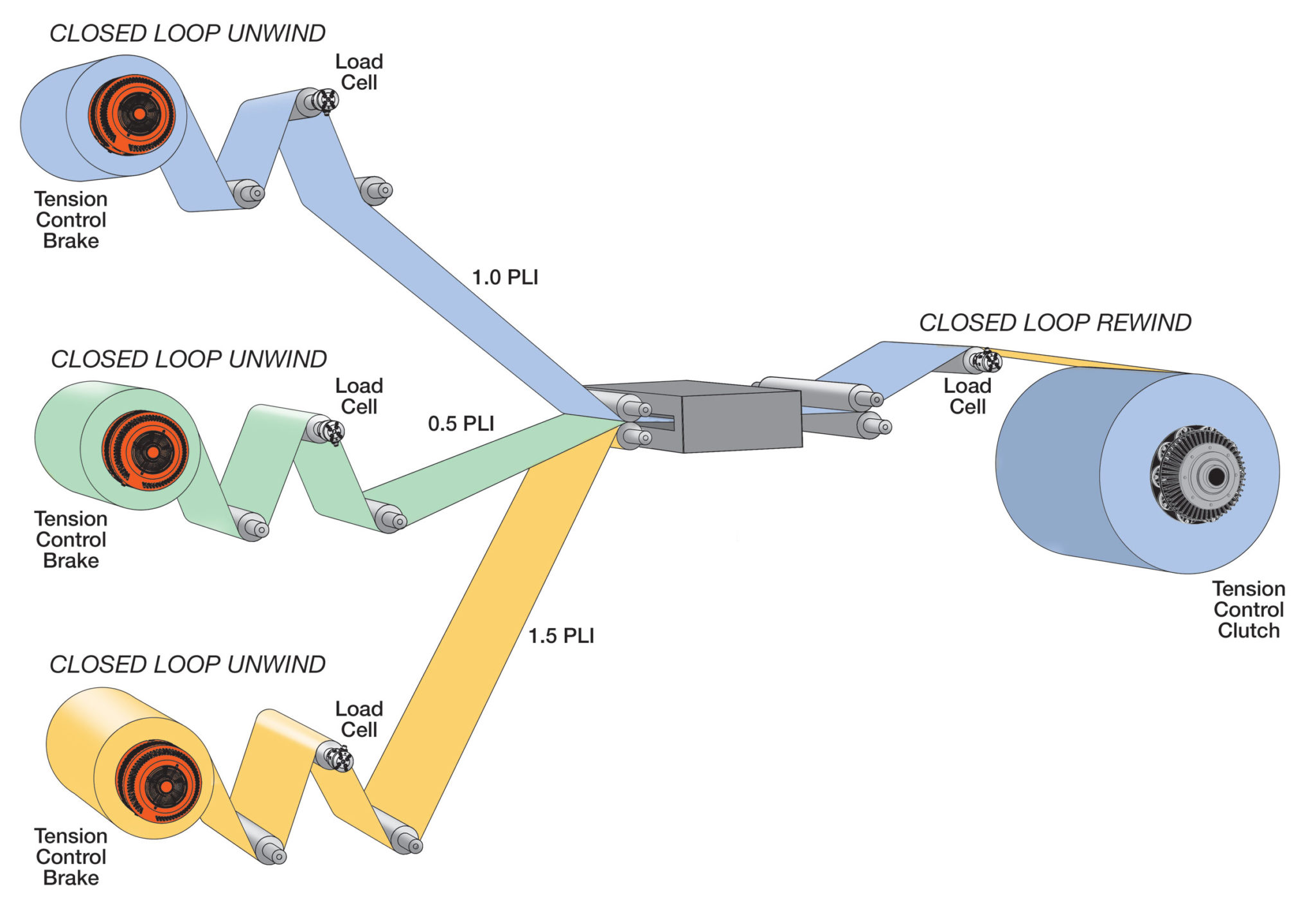

Laminating Processes

As two or more webs come together (general lamination, carrier sheets, surface veil, inter-leafing), each web may have the same or (more often) different characteristics and tension requirements. In order to ensure a high quality lamination process with minimal defects, a tension control system applied to each roll of material is a necessity.

Ensure every roll/material is at the precise tension it requires for high-quality production with Montalvo Tension Control Components.

Upgrade Your Lamination Process

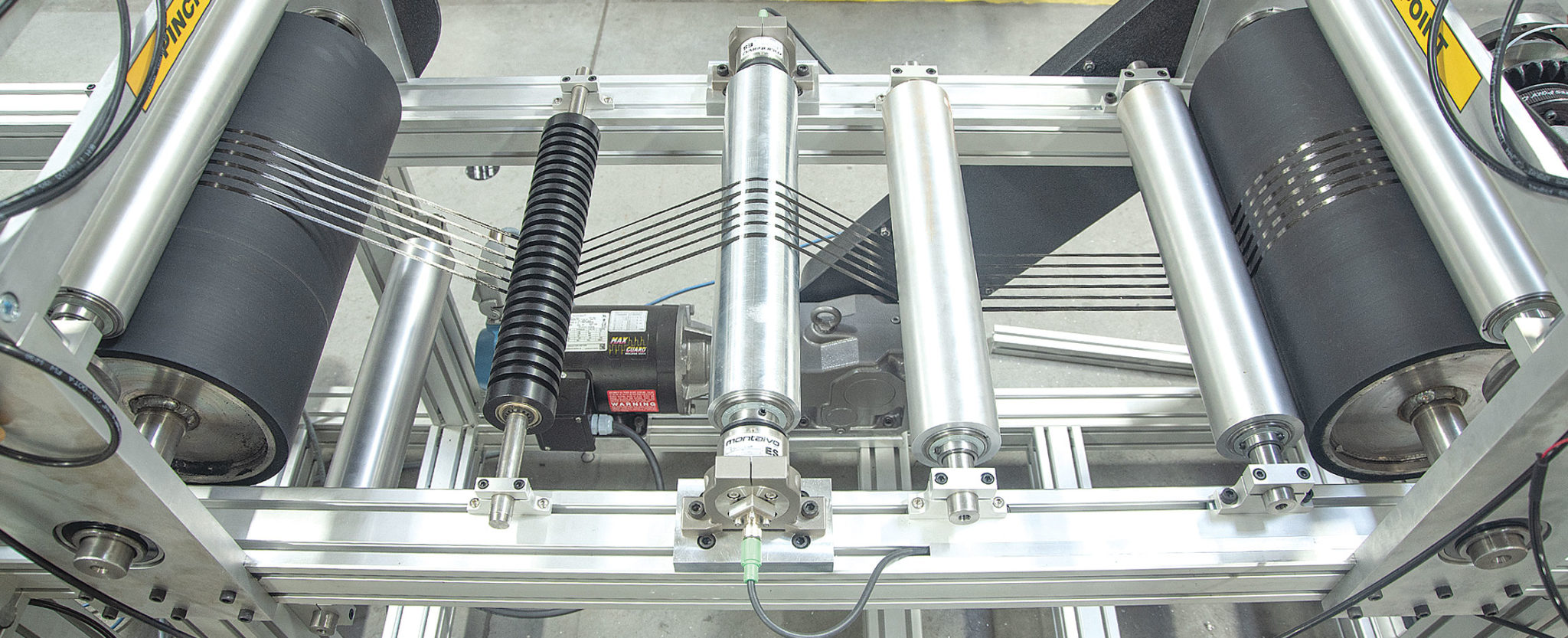

Converting – Slitting/Sheeting/R2R

All materials have unique processing requirements. Combined with the various processing requirements of the Converting process being employed, a high quality and wide-ranging tension control system to meet every demand is required. Montalvo’s tension control components give you the range, the performance, and the repeatability you require for increased productivity and reduced waste in your converting process.

Montalvo is an industry leader in the manufacturing of higher quality, higher performing tension control components that can be easily incorporated into new or existing applications for improved production. From Unwind to Rewind, Montalvo is here for you!

Upgrade Your Converting Application

Hand-Lay Applications

Montalvo has provided unique tension control solutions to add continuous production to hand-lay applications improving efficiency and quality. Depending on the nature of the hand-lay application, targeted tension control component additions can add new processing capabilities to hand-lay application you may not have thought possible.