In this issue:

TSC™ System – Patented Technology

Product Spotlight: EtherNet/IP™ for Z4 Tension Controller

Web Break Detection

TSC System with US4 Option

- Customizable System Packages

- Easy Installation, Set Up & Operation

- Easily Upgrade Existing Machines

- Smooth, Precise, Repeatable Tension Control from Full Roll to Core

- Compact & Space Saving Tension Control Package

- Faster communication between Z4’s and other networked devices

- Easily interface with existing HMI

- Parameters made available for customized tracking and logging

- Easily integrates into existing Ethernet system

Web Breaks are the bane of converting, printing, coating, and all applications. You rarely know in advance when a web break is going to happen, and when it does the operator is often at a loss to explain why it happened. Although a complete tension control system can greatly reduce the chances of a web break occurring, when a web break does occur it is the speed at which it is detected and action taken that determines the amount of time and product loss.

Although there are some general conditions that make web breaks more likely to happen, the specific circumstances that cause web breaks vary from application to application, from press to press, and from converting machine to converting machine.

On all Montalvo Web Break Detection equipped controllers users are able to program and adjust all web break detection settings, determining the level of sensitivity in triggering a web break signal, and creating the type of web break detection indication desired (ex: alarm, light, machine shutdown, etc.).

Web Break Detection comes equipped on the following Montalvo Controllers: X-3400 Tension Controller, Z4-UD Unwind Dancer Tension Controller, and the Z4-UI Unwind Dancer Tension Controller with Tension Indication. All controllers additionally feature a wide range of communicative, diagnostic, and performance enhancing features.

Here For You!

Need technical assistance, have a question about your application, adding components to a new machine, or want to explore an upgrade or retrofit, we are here to help you any way we can.

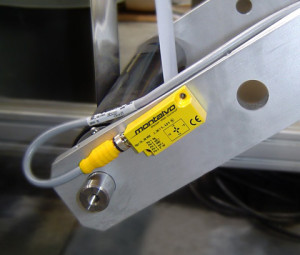

Auto Fault/Damage Detection of load cells

Auto Fault/Damage Detection of load cells

3 Pin Dead Shaft Idler Load Cells (DR-D Series – Dover Flexo Direct Replacement Load Cells):

3 Pin Dead Shaft Idler Load Cells (DR-D Series – Dover Flexo Direct Replacement Load Cells):